Bench Top Plasma Treatment System - PJ

PJ

bench top plasma unit

The PJ Plasma Surface Treatment System is a compact, user-friendly tool with all the functionality of our large batch gas plasma systems. Designed for both laboratory and production use, the PJ is versatile and can be used for a variety of plasma-based processes including cross linking and cleaning organic and inorganic contamination of various substrates such as metals, ceramics, glass, and silicon.

The PJ Plasma System is also ideal for improving lubricity, wettability, and bond strength. Other common applications include: medical devices, RGP contact lenses, printed circuit boards and electronics. The entire unit conveniently fits inside a single cabinet. Choose from Pyrex (standard), quartz, or aluminum chamber materials.

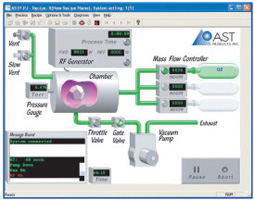

The PJ’s main user interface screen constantly displays all the key process information in real time. Information such as RF forward and reflective power, gas flow, operating pressure and process time are all clearly displayed. A message board also displays the latest process function. Operators can choose from an infinite number of pre-programmed processes or create a new recipe. All parameters can be modified in-process from this main screen.

PJ Specs:

Main 115 VAC, 15 amp

RF Power 300W 13.56 MHz

RF Match Automatch

Control Software controlled via PC

Footprint: W 24” x L 24” x H 12”

Weight 75 lbs.

Chamber 8” diameter, 10” depth Pyrex Capacitively coupled

PJ Options:

Choice of chamber material:

Pyrex, quartz, and aluminum

Pump filtration system

O2 service on pump

Mist filter on pump

Capacitance manometer

Throttle valve

Vacuum pump, 11 cfm, 115v, 15 amp

2nd MFC

Notebook PC

Gas Feed:

One MFC included

Choice of chamber material

AST Plasma Science

AST has long had a core business in plasma processing. Backed by the company’s superior expertise in surface modification, coating and contact angle measuring technologies, AST/Plasma Science group provides the best knowledge to work with our customers for critical process development.